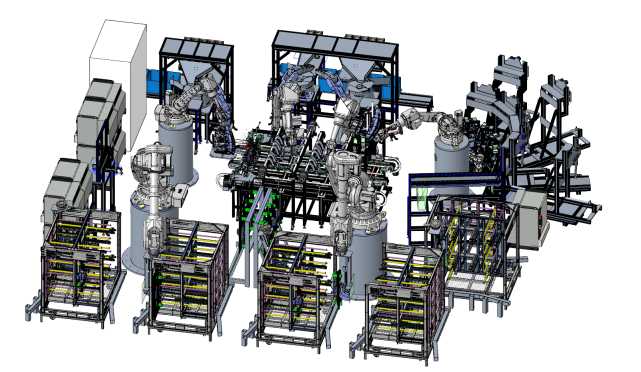

Complete turnkey delivery of automation from A to Z. We can supply any equipment from simple jigs, through single-purpose machines to automatic robotic lines.

Implemented projects

Anyone who wants to reduce costs, replace human labour, speed up or streamline the production process can contact us.

We provide complete automation from A to Z within our company, whether it is concept design, construction, manufacturing,

assembly, electrical design, electrical assembly, safety circuit design, control system programming and robotization.

An integral part of the project scope is installation, commissioning and training at the customer's site.

After the project is handed over, we provide the customer with servicing of the equipment supplied by us with the possibility of supplying spare parts.

We will prepare a study with a detailed description and a quotation for any request. Almost every offer includes a 3D visualisation of the technical solution of the concept.

There is no project that we cannot offer, from simple jigs trough single-purpose machines to fully automatic complex robotic lines.

The design department has more than 20 years of professional experience and expertise in machinery design.

For the fastest possible production we use "drawing-free production", in which we work only with 3D models, even in production and assembly.

We use the latest PTC CREO software for the design.

We use 3D models in the production, where production operators have their own tablet that is used to produce any component using 3D models to the required accuracy.

We carry out the complete production of parts and subsequent assembly within our production hall, and we also use production technologies and capacities throughout our company.

This stage works closely with production and design, suggesting improvements and modifications during the initial assembly of the equipment or line.

For faster and clearer assembly, we use clear large-scale projection visualizations directly in the hall.

The complete electrical project is designed by our experienced designers, including important safety features in accordance with applicable standards and regulations, and they routinely work with TÜV certified auditors.

We use EPLAN software for designing.

The implementation of the designed projections is also carried out in our company by a team of experienced electricians.

Our team of programmers mostly uses SIEMENS and MITSUBISHI PLC systems.

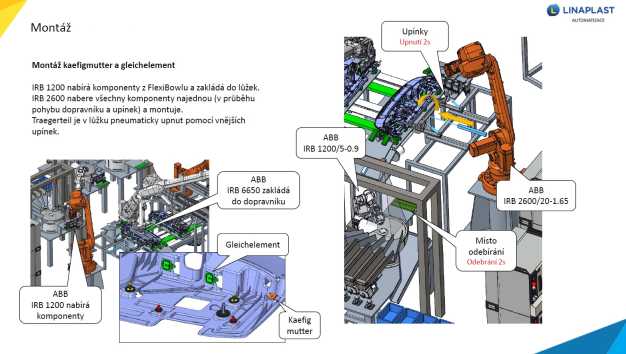

We routinely implement robots from world-renowned brands such as ABB, KUKA and FANUC.

Furthermore, we are able to prepare customized database and other PC applications, and we regularly communicate with systems for data collection from production.

We focus on modern technologies such as "bin picking", i.e. the selection of loose components for subsequent assembly.

An integral part of every machine or line is a risk assessment carried out by qualified external experts.

Every piece of equipment or production line leaves us tested, safe for use and meeting specified customer requirements.

Installation at the customer's site is carried out at a pre-arranged time according to the customer's needs with the participation of workers who are involved in the entire project from the beginning; by doing so we strive for the shortest installation time and prevent any delays.

We focus on meeting all customer requirements within the specified deadline.

Operator and maintenance training and follow-up service are also integral parts of the service.

We use the most advanced technologies on the market. We take special care in the selection of technologies, we look for new trends and apply them to our solutions. We thoroughly test all these technologies before implementing them with our customers.