The tool room is equipped with the most modern machines of world brands, which are operated by qualified workers with many years of experience. Our products are used by many domestic and foreign customers. See our portfolio. We use our years of industry experience to improve our products and services to meet the increasing demands of our customers.

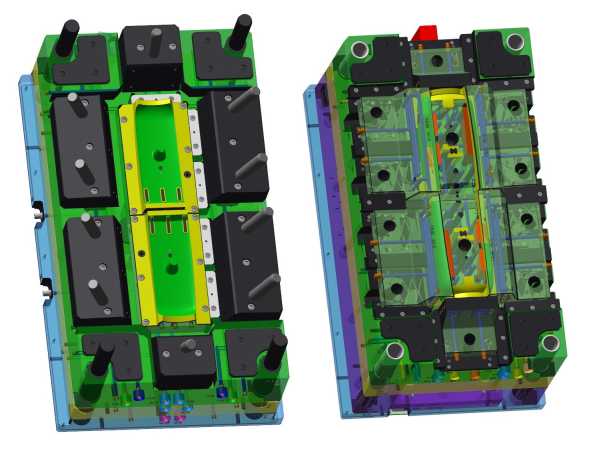

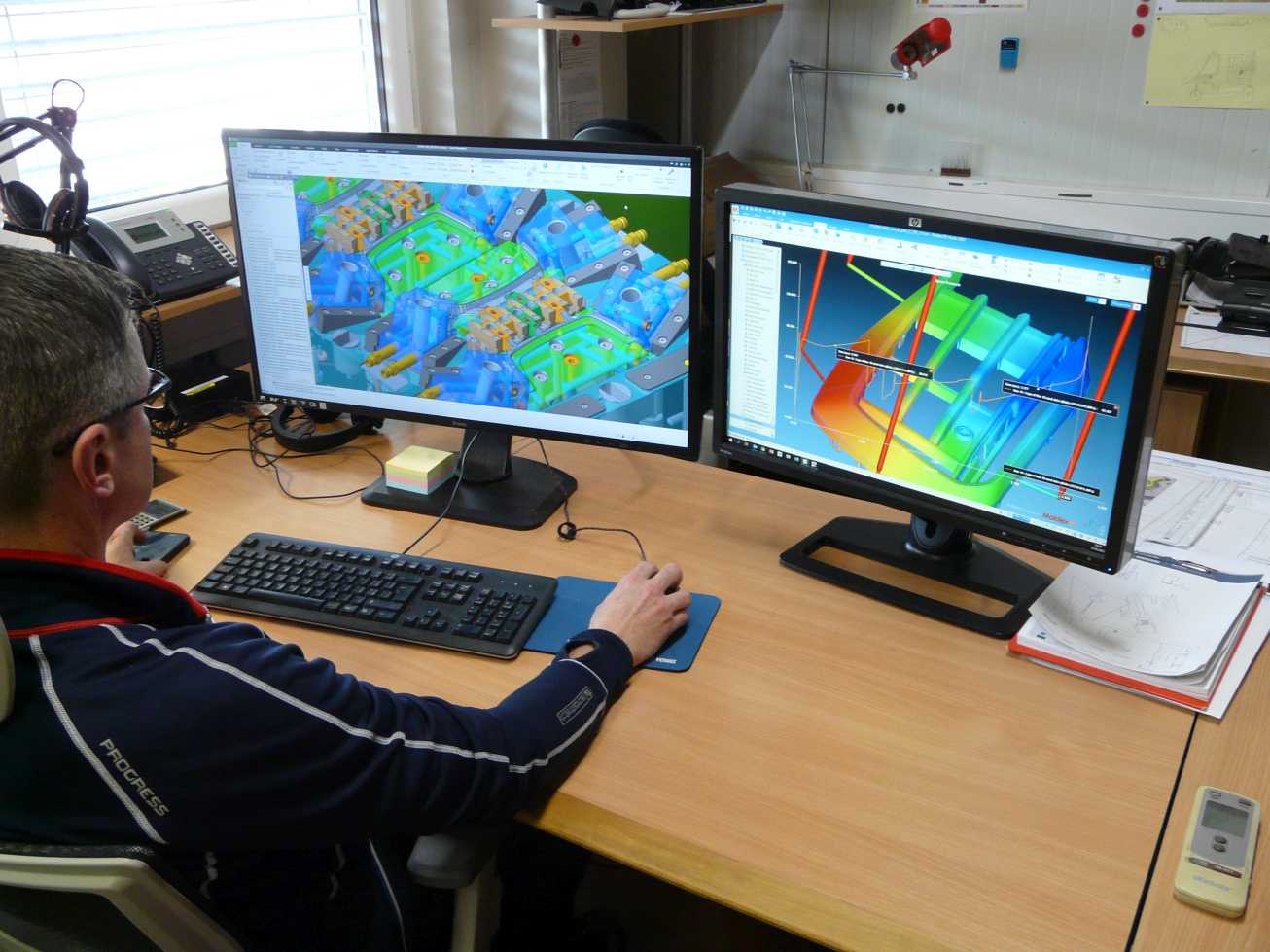

Our designers use the latest PTC CREO software.

Each product and mould design undergoes a thorough Moldflow analysis. We use MOLDEX 3D software for this purpose. Based on our analysis and experience, we specify the scope of pre-deformation of parts, which we then implement in the mould production.

To speed up production, we use only 3D models of mould designs and minimise the use of 2D documentation. This helps us to speed up the whole mould production process.

We emphasize customer satisfaction, therefore an individual approach and a high level of professionalism is necessary to satisfy all requirements.

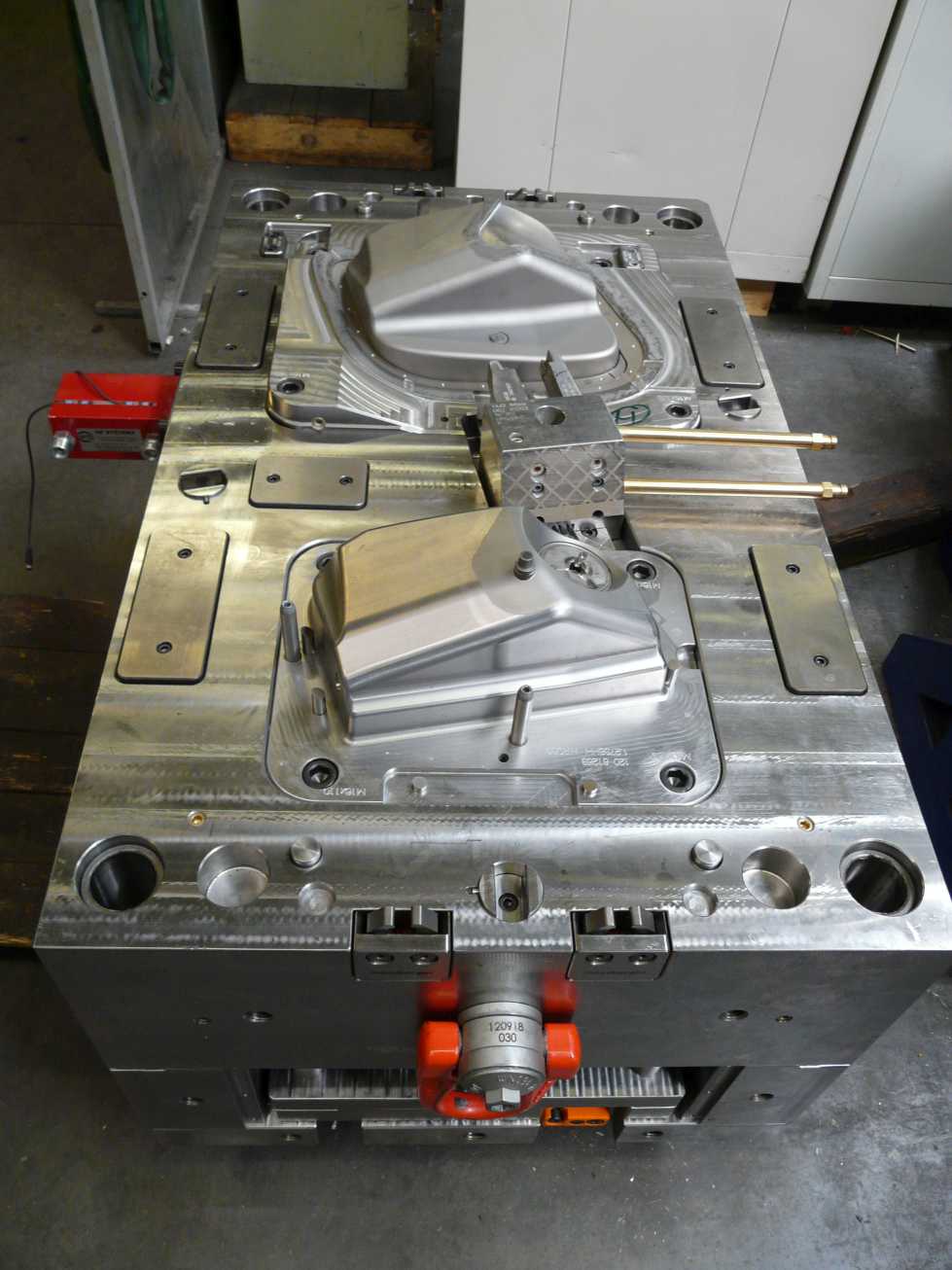

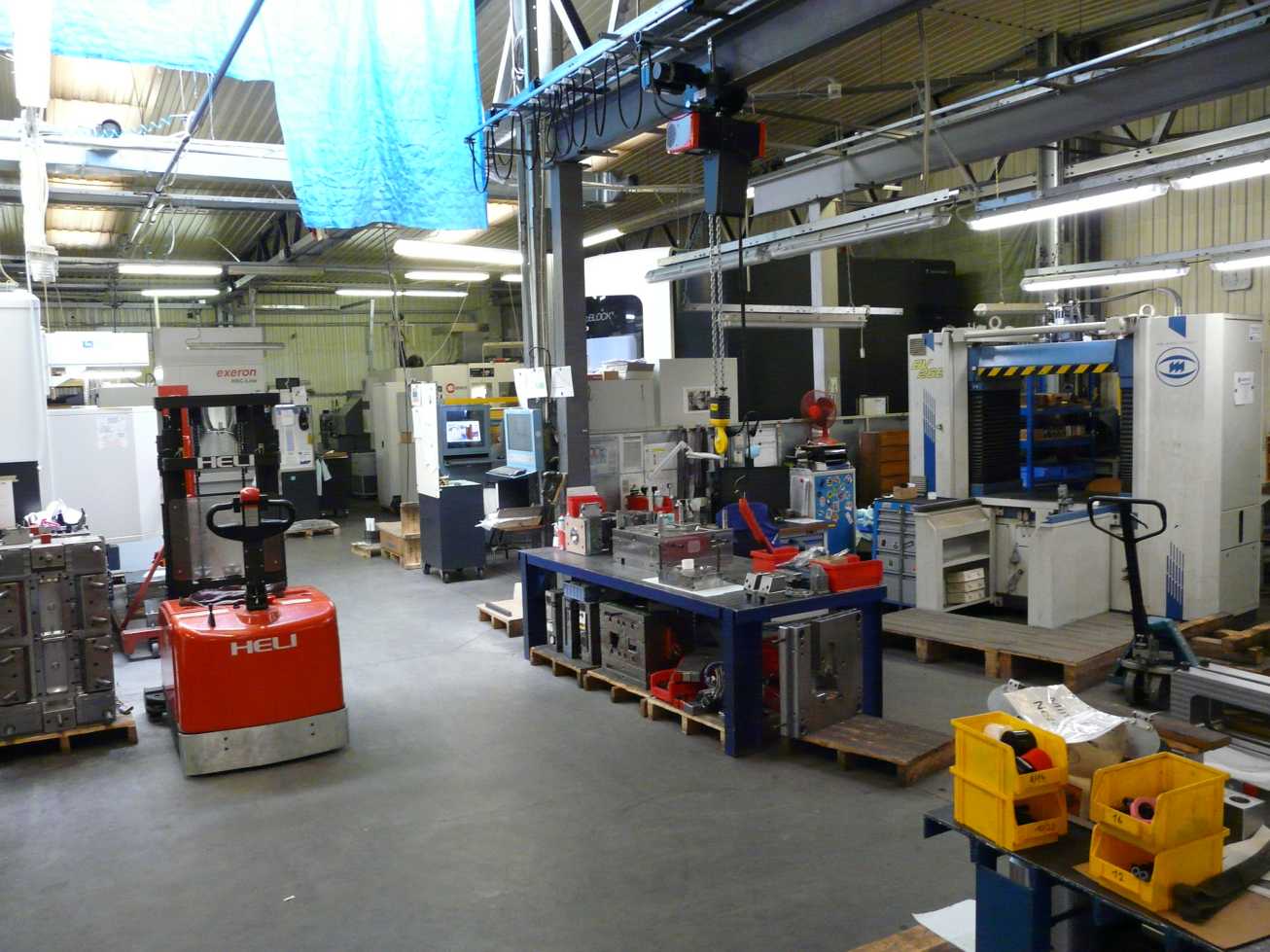

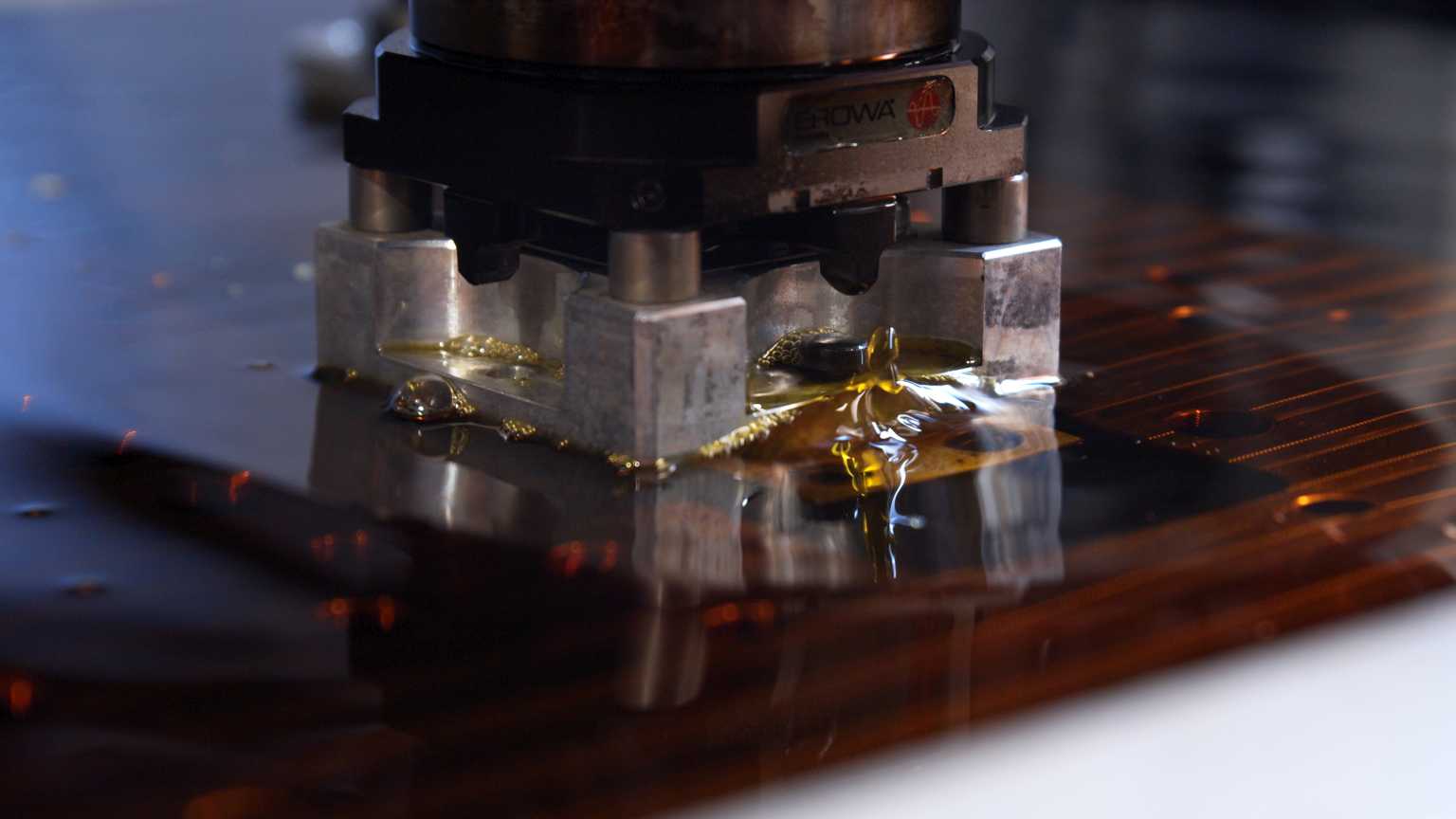

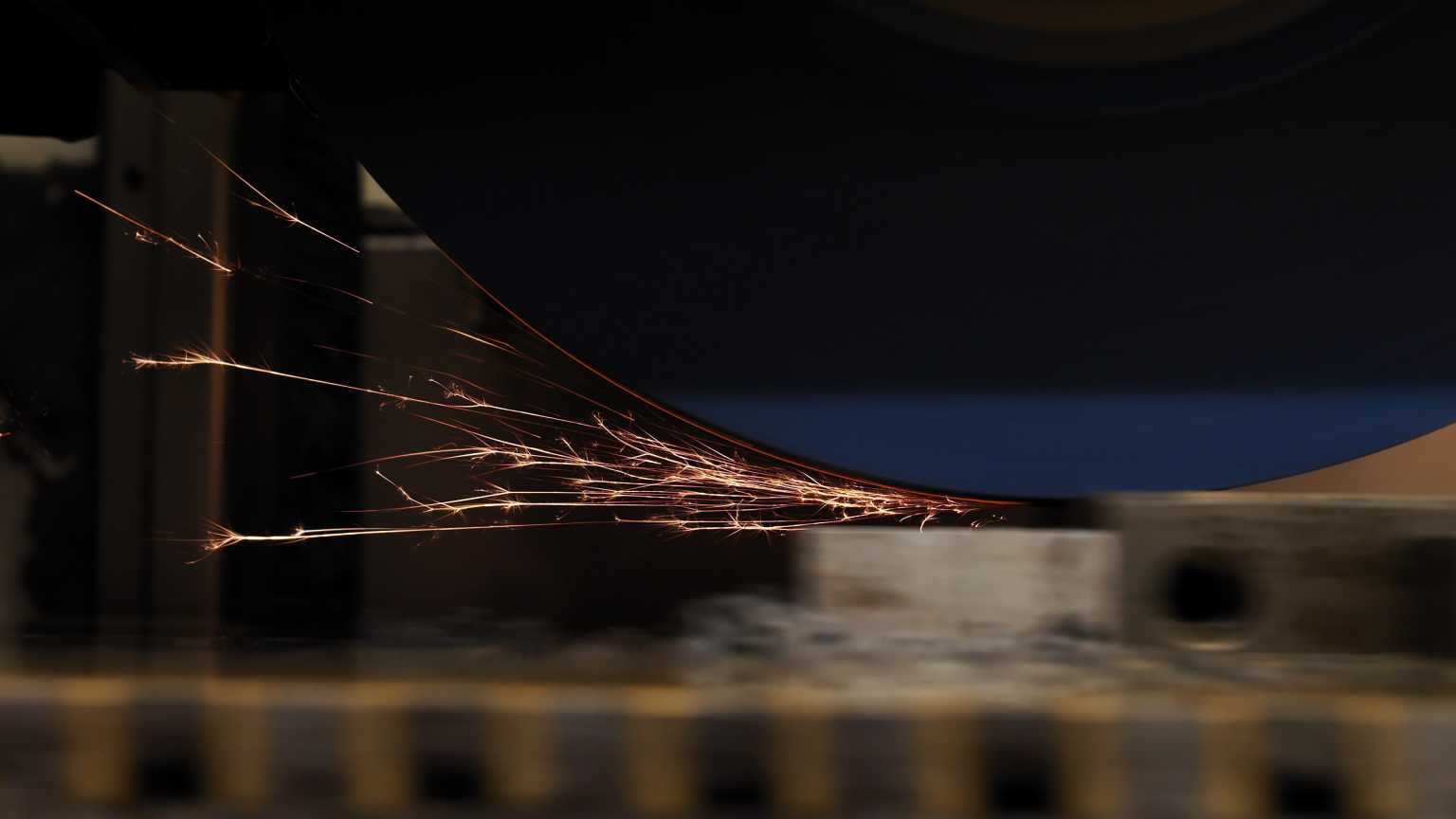

Our own machinery allows us to produce moulds completely in our tool workshop. We have 3-axis and 5-axis CNC machining centres, EDM, grinding and conventional turning, milling and drilling equipment.

We use PowerMill and PowerShape software for NC machining.

We normally process various types of steel, aluminium, plastics (POM, Sikablok, ...), etc.

For electrode production we use graphite and copper.

The tool room is equipped with the most modern machines of world brands which are operated by qualified workers with many years of experience.

Our products are used by many domestic and foreign customers.

We use our years of industry experience to improve our products and services to meet the increasing demands of our customers.