Modern technology, compared to laser cutting, does not produce harmful gases or radiation. The cutter can cut a variety of materials (paper, leather, artificial leather, foam boards, etc.) up to a length of 3,050 mm, width of 1,550 mm and thickness of 50 mm. Unlike using a laser, we are able to cut flammable materials (paper, foil, etc.) with no problem, and we have also the advantage of not needing expensive templates for die-cutting in piece production.

One of the many customers we supply to is VW. It also includes ultrasonic welding of parts, where one material is fixed and the other is vibrated by the frequency of the ultrasonic conductor. The advantage is less thermal influence on the joint, due to which the material properties do not change.

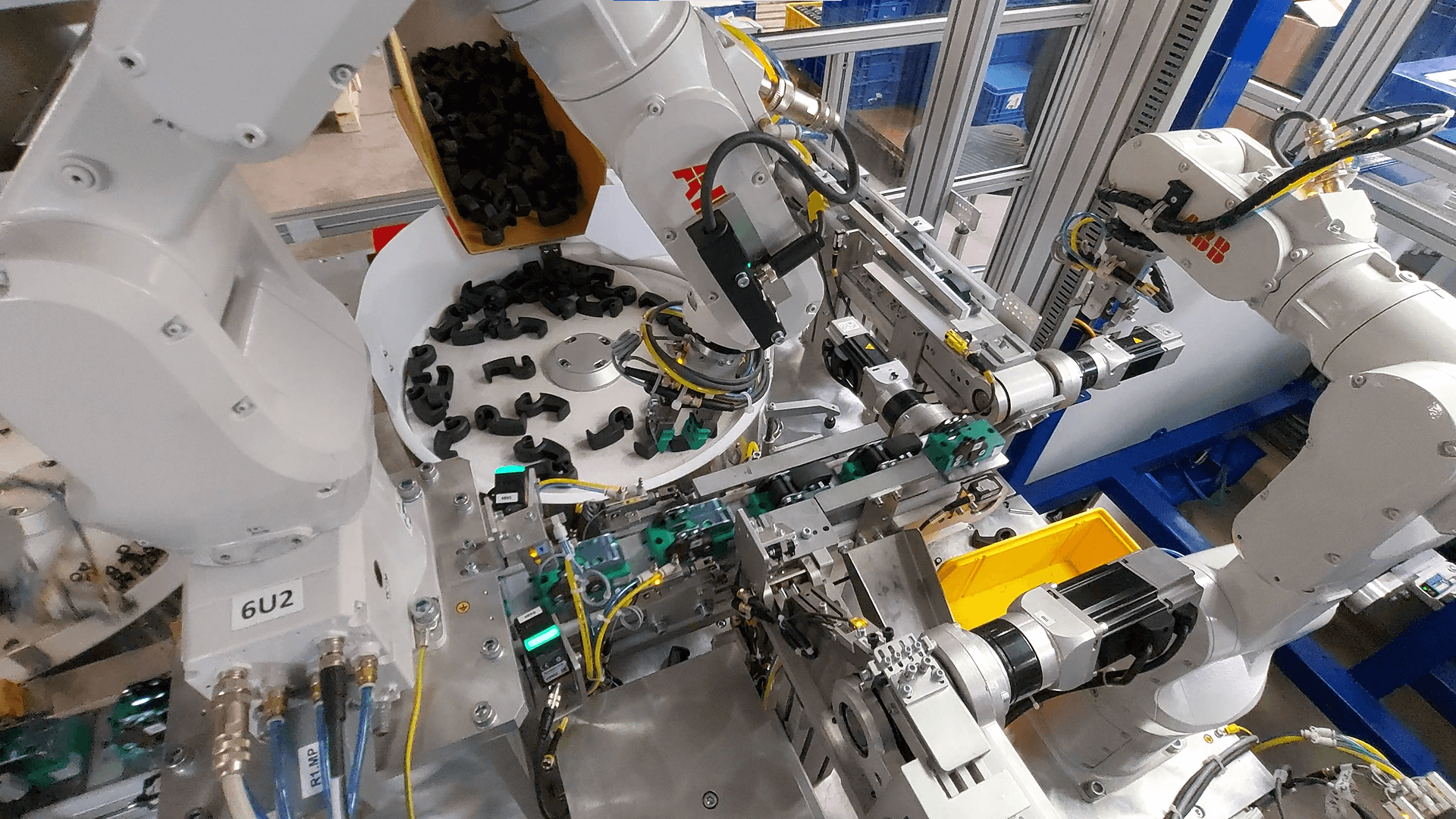

Where possible, we use automated assemblies that we can design and manufacture. The video shows the assembly, description and control of the hook in cars, for example Octavia.

Since not everything can be solved automatically, we also have manual assembly.

The laser is most often used for laser-printing symbols on the gearshift covers. It is possible to laser-print even non-planar objects, e.g. shift lever plaquettes. We are also able to engrave on metal to a lesser extent.

Progressive and precise technology in which a thin layer of metal foil is applied to plastic parts. It is a clean technology in which the parts do not need to be soaked in the solution for embossing.

The resin socketing technology secures the connectors against moisture ingress and weather conditions, and ensures a "screwless" connection of the connectors in the plastic parts.