Fully automated assembly line for mounting hooks into the luggage compartment of Skoda vehicles.

The line is equipped with four "ABB IBR 1100" robots and "Flexibowl" Bin Picking technology, and selection of loose components.

The line is completed with calibrations, mechanical and visual checks.

Client: LINAPLAST s.r.o.

Year: 2021

Contribution of implementation:

Delivery of a complete headlight assembly line to a new plant in Niemce, Poland.

Client: Varroc Lighting Systems, s.r.o.

Year: 2018

Contribution of implementation:

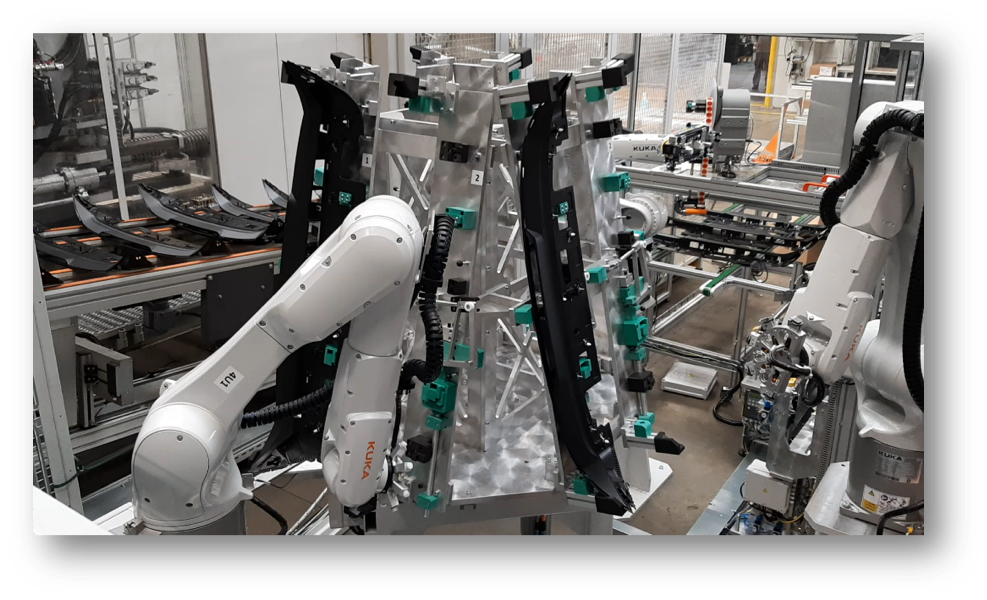

Delivery of assembly line for the assembly of the VW rear spoiler support part.

Assembly and check of the presence/position of the components to be assembled takes place in the pressing cycle.

Plastic clips, bolts with nuts and clamps are assembled on the line.

Client: REHAU, s.r.o.

Year: 2019

Contribution of implementation:

Conversion of automatic clip station for wheel sill trim. The delivery included new beds,

clip stations, clip feeding and programming work.

Client: MAGNA Exteriors (Bohemia) s.r.o.

Year: 2019

Contribution of implementation: